The following is a time line and my thought process as I developed the Dragvette 6-Link

In Dec 29. 2004 thoughts and plans to build a six link suspension for my 73 had formed This was only the beginning of a long slow process to focus on a project that would be interrupted repeatedly while living life day to day.

March 26, 2005 Not much happening on the project. I have gotten the seats back from the upholster they look real nice and were 300.00 for the pair I provided the seat covers they came with the car.

May 9, 2005 Has it been that long! I have been a little distracted with the addition to the shop. Six hundred square feet and 10,000 lb car lift they were way over due. Well it's not a big surprise the left front brake caliper went bad from sitting around and not being used on a regular basis. I always bleed my brakes at the beginning of every race season on the 76 and this 73 will not be any exception. A little tip for you guys that haven't done this little exercise much. It helps to jack the end of the Corvette up depending on which end your bleeding. That is jack the front up if your bleeding the front brakes and jack the rear up if your bleeding the rear brakes. Air bubbles float up stream it seems to help. Also bleed the brake closest to the master cylinder. Front driver, front passenger, rear driver, rear passenger, in that order. I need to bolt the seats in.

Jan 6, 2006 The addition to the shop is complete. I thing I will make a DVD of the IRS build up. I can use it for an instructional DVD. The only problem is it will slow me down a bit. I have many people wanting to purchase the

6-link system as soon as it available. I have talked a lot about it and I am finally in position to start making things happen on it. So hold tight its launch time.

In Dec 29. 2004 thoughts and plans to build a six link suspension for my 73 had formed This was only the beginning of a long slow process to focus on a project that would be interrupted repeatedly while living life day to day.

March 26, 2005 Not much happening on the project. I have gotten the seats back from the upholster they look real nice and were 300.00 for the pair I provided the seat covers they came with the car.

May 9, 2005 Has it been that long! I have been a little distracted with the addition to the shop. Six hundred square feet and 10,000 lb car lift they were way over due. Well it's not a big surprise the left front brake caliper went bad from sitting around and not being used on a regular basis. I always bleed my brakes at the beginning of every race season on the 76 and this 73 will not be any exception. A little tip for you guys that haven't done this little exercise much. It helps to jack the end of the Corvette up depending on which end your bleeding. That is jack the front up if your bleeding the front brakes and jack the rear up if your bleeding the rear brakes. Air bubbles float up stream it seems to help. Also bleed the brake closest to the master cylinder. Front driver, front passenger, rear driver, rear passenger, in that order. I need to bolt the seats in.

Jan 6, 2006 The addition to the shop is complete. I thing I will make a DVD of the IRS build up. I can use it for an instructional DVD. The only problem is it will slow me down a bit. I have many people wanting to purchase the

6-link system as soon as it available. I have talked a lot about it and I am finally in position to start making things happen on it. So hold tight its launch time.

April 21,06. The 6 link for our favorite IRS is taking shape. It's not a big surprise the first proto type has a number of issues. After all of the thought and effort with the first proto type I am already making changes with this unit as you are reading. The number one change I will be making is to make the bottom link the same length as the half shaft. The one shown is 16 inches long that's 1 1/2 shorter than the stock unit. It still needs to be about 2 inches shorter before it will be acceptable for our needs. That being done it will need a proper mounting bracket. That is practically completed. The second issue I have it the top mounting link for the upper strut rod is to tall and interferes with the body under heavy roll conditions. I already have a different mount design in mind it should allow another 1 1/4" of clearance which should be plenty of clearance. That will put my mind at ease. The plate that I normally use to relocate the strut bracket has been reduced from 1" to 1/2". That will have a domino effect and will cause a number of dimensional changes. It will help reduce the interference problems with the stock exhaust system and align the bottom strut rod to the perfect mounting position.

April 23, 06 I have put some thought into marketing the new 6-link. Greenwood offered a 6 link system for a short period of time only a few kits were sold. The reason was simple why it did not become a traditional upgrade for Corvette owners every where. It was simply to costly for the average person to purchase. Billet castings and stainless steel are great but add a great deal of expense to the price tag for the consumer. There may have been other issues such as poor marketing and any other number of unknowns. If the internet had been available to Greenwood he would have a lot better chance of success.

April 23, 06 I have put some thought into marketing the new 6-link. Greenwood offered a 6 link system for a short period of time only a few kits were sold. The reason was simple why it did not become a traditional upgrade for Corvette owners every where. It was simply to costly for the average person to purchase. Billet castings and stainless steel are great but add a great deal of expense to the price tag for the consumer. There may have been other issues such as poor marketing and any other number of unknowns. If the internet had been available to Greenwood he would have a lot better chance of success.

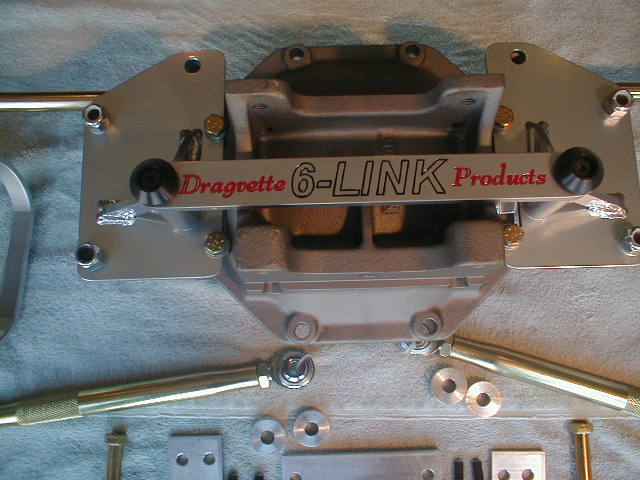

April 28,2006 As you can see from the picture above the mount on the top of the 6-link system has been changed. The former mount was easy to build but it was to tall. It was able to contact the body on heavy body compression. We all know that the drivers that use our products will push there machines to the limit so the mount had to be modify to minimize mounting height so the suspension would no longer present the possibility of body interference.

Here is a view of the new mounting location of the strut bar. After measuring the amount of movement with a 16" long strut bar we determined the only way we were going to get the 6-link to work properly would be to use a strut bar exactly the same length as the half shaft and create a mount that would allow the strut bar to be parallel to the half shaft as you can see the strut bar is the same exact length as the half shaft and it will forms a perfect parallelogram. Without a top link bar, the wear in the posi-tract clutch plates allow movement in the side yokes. The top link will stabilize the movement of the side yoke and provide support for the Corvette should the half shaft decide to take an alternate path down the track or street.

May 7,2006 WOW I have been able to finish the 6-LINK!! I know that many of you have heard about this happening and being in the works for years. I was finally been able to focus all of my attention on this project. I am glad to be able to say I have resolved all of the issues I had with the design and I am very pleased with the out come. In order to determine how perpendicular the tire was to the ground I set a digital protractor on the brake rotor and moved the suspension through it entire range of motion about 8 inches. The protractor varied .2 of one degree that is a total of .0096 variation on a 28 inch tall tire. here are a few quick shots of the proto type I took with my digital camera.

Here is a view of the new mounting location of the strut bar. After measuring the amount of movement with a 16" long strut bar we determined the only way we were going to get the 6-link to work properly would be to use a strut bar exactly the same length as the half shaft and create a mount that would allow the strut bar to be parallel to the half shaft as you can see the strut bar is the same exact length as the half shaft and it will forms a perfect parallelogram. Without a top link bar, the wear in the posi-tract clutch plates allow movement in the side yokes. The top link will stabilize the movement of the side yoke and provide support for the Corvette should the half shaft decide to take an alternate path down the track or street.

May 7,2006 WOW I have been able to finish the 6-LINK!! I know that many of you have heard about this happening and being in the works for years. I was finally been able to focus all of my attention on this project. I am glad to be able to say I have resolved all of the issues I had with the design and I am very pleased with the out come. In order to determine how perpendicular the tire was to the ground I set a digital protractor on the brake rotor and moved the suspension through it entire range of motion about 8 inches. The protractor varied .2 of one degree that is a total of .0096 variation on a 28 inch tall tire. here are a few quick shots of the proto type I took with my digital camera.

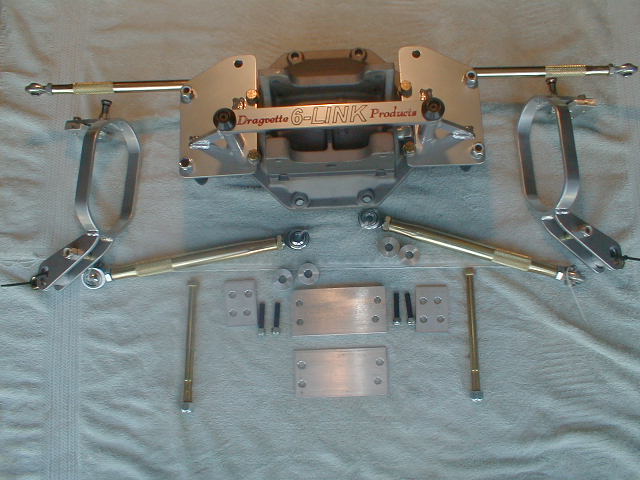

The picture above are the parts of the proto type 6-link. the pictures below are pictures of the proto type 6-link installed on the 73 project car.

Notice the additional safety loop on the half shaft next to the differential. Another feature is the horizontal bar that runs across the back of the rear cover connecting both sides of the 6-Link. This will give the rear pig more rigidity Just like a rear cover girdle. There are additional gussets welded on the center section support you are viewing here. This is just one of the development stages.

Below is another picture of the 6-Link in development. Please note this is not the finished product this is a picture of the unit in development. Product pictures will be posted in the next week or so. I will currently be tied up editing an instructional DVD that actually shows installation of the 6-Link.The DVD can be seen on this site under Instruction at the top of the header.

Below is another picture of the 6-Link in development. Please note this is not the finished product this is a picture of the unit in development. Product pictures will be posted in the next week or so. I will currently be tied up editing an instructional DVD that actually shows installation of the 6-Link.The DVD can be seen on this site under Instruction at the top of the header.

I am pleased to announce Dragvette Products has finished the development of the 6-link and we will now offer it to our customers at the prices stated above. (Most Dragvette 6-Link Suspension Systems are available for $895.00 plus shipping.

The above right picture is a disassembled view of the same upper link. The securing shoulder bolt has a 1/2" body with a 3/8 thread, it also features a nylock insert on the thread so the securing nut will not back off.(This has been updated to a 1/2" fine threaded bold and 1/2" Nyloc Nut. These pictures are left on the site to demonstrate the developmental steps of our product this design has been superseded since july 30,06)

The picture above is a front and rear view of the center section plate. As you can see gussets were added to insure the maximum strength in the weldment to minimize deflection in the center section. The zinc plated hiem joint (above) is reflected in the finish of the safety loop and it doesn't appear to have a finish that is any better then the safety loop. ( Today's 6-Links use a satin black paint finish)

There has been some discussion as to weather the clips on the side yokes are required for this system as I see it you may keep the clips on if the rear end is worn and the side yokes have a 1/8" play. It is my opinion especially when the differential has been rebuilt we strongly recommend the clips be removed.

It has been asked if Tom's Differentials rear ends are compatible with the Dragvette 6-Link System. As of March 22,07 Dragvette Products offers a 6-Link that is compatible with the Tom's trailing arms and the over sized half shafts and 1480 joints. We also fit all other stock and aftermarket trailing arms including offset trailing arms. We are continually accommodating more after market systems. Case in point is the recent development of a 6-Link that is compatible with the VB & P dual mount mono spring.

I took the 73 Vette out for a seat of the pants test spin. I was impressed by how flat the Corvette cornered as this Corvette does not have a rear stabilizer bar, fancy tires or an alignment tuned for cornering. I don't know what the minimum turning circle of the Corvette is but after 5 or 6 tight circles I found myself quite dizzy after straitening the wheel out. This was on asphalt and I was surprised the wheels were not squealing they just seemed to grip incredibly well. Sure I would be biased but if there was anything at all not to my liking or unusual in a handling sense I would have to have to include that in my seat of the pants test. Dragvette is committed to quality products and we have always had a 100% refund policy no explanation needed but appreciated as it may be some valuable feed back.

There has been some discussion as to weather the clips on the side yokes are required for this system as I see it you may keep the clips on if the rear end is worn and the side yokes have a 1/8" play. It is my opinion especially when the differential has been rebuilt we strongly recommend the clips be removed.

It has been asked if Tom's Differentials rear ends are compatible with the Dragvette 6-Link System. As of March 22,07 Dragvette Products offers a 6-Link that is compatible with the Tom's trailing arms and the over sized half shafts and 1480 joints. We also fit all other stock and aftermarket trailing arms including offset trailing arms. We are continually accommodating more after market systems. Case in point is the recent development of a 6-Link that is compatible with the VB & P dual mount mono spring.

I took the 73 Vette out for a seat of the pants test spin. I was impressed by how flat the Corvette cornered as this Corvette does not have a rear stabilizer bar, fancy tires or an alignment tuned for cornering. I don't know what the minimum turning circle of the Corvette is but after 5 or 6 tight circles I found myself quite dizzy after straitening the wheel out. This was on asphalt and I was surprised the wheels were not squealing they just seemed to grip incredibly well. Sure I would be biased but if there was anything at all not to my liking or unusual in a handling sense I would have to have to include that in my seat of the pants test. Dragvette is committed to quality products and we have always had a 100% refund policy no explanation needed but appreciated as it may be some valuable feed back.

June 3,06 This is a complete kit with the exception of the 8" long screws that are needed to adjust the half shaft level with the street or track. The Dragvette 6-Link Suspension System is shipped semi assembled to make your installation process easier. We also send a DVD installation video with each 6-LInk. The DVD shows every step of installation and adjustment it is approximately 1 hour in length. The girdle bar in the center of this kit will be included in all kits " Dragvette 6-LINK products " inscribed on the girdle. It is one of the finishing touches that is still on going. We also have a couple of small refinements tha will be added. Please note any updates that are made and have any significant benefit for a Dragvette 6-Link Suspension System will be sent free of charge to any customer that has already made a purchase. Dragvette service and a great product is what will make Dragvette Products a great company to deal with.

July 9/06. Here's a look at the latest Dragvette 6- Link Suspension System. This unit is headed to Patrick Armstrong of Michigan, We have delivered a previous unit to Leon Sabelka of Iowa. We are currently working on unit for Hennik Anderson of Sweden, Brad Ecker of Maryland, Vasco Arosemena of Panama, Andrew Hodgson of Australia, Jason Mackey of Indiana, and Micheal Dobesh of Alaska.

Oct 9,2006 We have currently delivered 15 Dragvette 6-Link Suspension System and we are just now receiving some customer feed back. The first kit immediately ran into a heavy duty aftermarket rear cover. So we made some adjustments. We also decided the drain plug needed to be a little more accessible so once again we made another adjustment. So there were basically two small issues and one bigger issue that were all addressed. We also issued the upgrades to any customers that had not received those items to begin with at no additional charge not even shipping.

Please note the heavy duty cover is not included in the Dragvette 6-Link Suspension System. They are in the pictures to give you a reference as to its location to the rear differential. Heavy duty covers are available through us for $149.00.

Oct 9,2006 We have currently delivered 15 Dragvette 6-Link Suspension System and we are just now receiving some customer feed back. The first kit immediately ran into a heavy duty aftermarket rear cover. So we made some adjustments. We also decided the drain plug needed to be a little more accessible so once again we made another adjustment. So there were basically two small issues and one bigger issue that were all addressed. We also issued the upgrades to any customers that had not received those items to begin with at no additional charge not even shipping.

Please note the heavy duty cover is not included in the Dragvette 6-Link Suspension System. They are in the pictures to give you a reference as to its location to the rear differential. Heavy duty covers are available through us for $149.00.